This is a new section that I'm devoting to exhaust systems. This came to be as an offshoot of the effort with the JagdPanther. When I posted a brief video of the JagdPanther running from my YouTube account to RC-Panzerketten-Forum it raised some comments about how loaud it was. So in this day and age of self where people can legitimize complaints about such sounds ( yet nobody raises an eyebrow about pop and rap "music" played at obscene levels) we must pay attention to such things. Anyway I begin with the JagdPanther and my efforts to attenuate the sound somewhet. Below is a reprise of the video and verbage from the JagdPanther page.

I've begin disecting the frequencies of the exhaust note and I find that the area for the audio that seems to have the greatest impact is the range between 1 to 6 Khz. I've begun a search on muffler theory to see if there is any way I can attenuate this band. I found that the "Flammvernichter" type exhaust stacks I implemented offer the least resistence to the sounds of the high revving Webra 40 ;it seems much less than the Type A exhausts. The comments I received on the Kettfahrzeug forum while biting were true. The exhaust note of this model is especially loud even to me. So if just a video of it is loud how much worse in person. It behooves us to pay attention to such things. I'll never be successful in having it sound like a deep throated Maybach V12 but I should be able to inprove on the high pitched sharpness; I believe even a little will help a lot.

As I mused initially as this is pertinent to all my models I decided to make a separate page of it. Part of my inspiration for jumping into this subject came from reading this research article published in 1954; Theoretical And Experimental Investidation of Mufflers... in it the researchers take a wholely scientific approach to muffler design and effects. Many equations are promoted to determine the mufflers' characteristics. My higher math skills were fiarly rusty but I had no problems following the work for several of the examples they described. The one problem with the subject is that they targeted the frquency band of around 700Hz whereas I feel my trouble area is the aforementioned 1 to 6 Khz. They also only explored straight through designs because since this was a strictly aeronautical engine muffler study they did not want any back pressure. Not being concerned with that last constraint I examined the elements that seemed to affect the higher portion of the frequency band they were interested in and assumed that the effective band would comtinue into my target ramge or at least harmonics would have a positive effect.

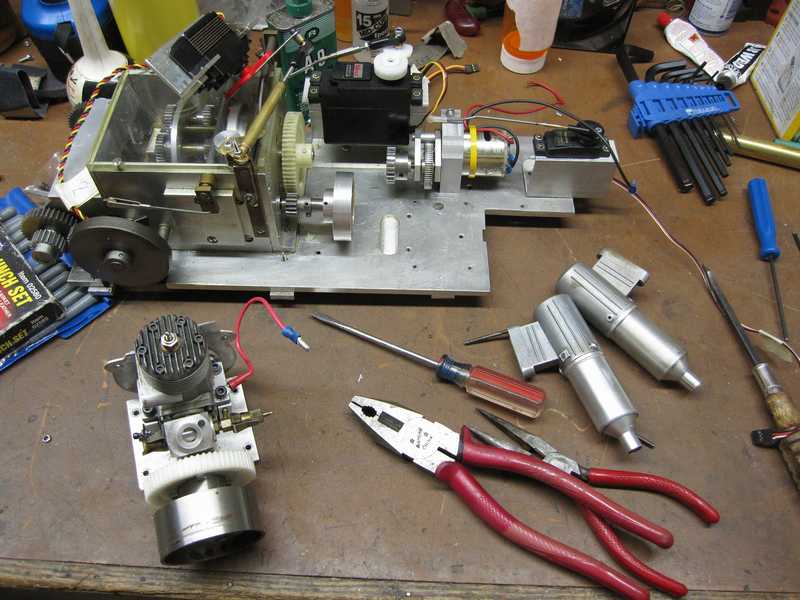

The test stand:

The test stand I used fr the miffler comparison test. The engine is a Silverline Webra 40 Blackhead, uunmodified in anyway. The carburettor is set reasonably lean..The two mufflers I used for the test are off to the left of the engineThe left most is stock, straight through and to its right is my modified version. I did not record the test but I could tell the difference immediately. The modifications I made are detailed below:

The completed muffler is in the last photo. From the third photo it is not fully apparent but the section of the center pipe with the vent holes is to the right of the perforated baffle disc; in the section of the muffler body that is turned. I've neglected to point out that the cast portion of these mufflers was made with a center piece cast in them that was clearly meant to accept a center pipe as you see in these photos. By the most fantastic bit of luck I found I have a great length of thin wall aluminum tubing that fits this mounting absolutletly perfectly just as if they were made for each other. It is a short section of this tubing you see in the photos, cut to length. I turn the end that goes into the turned section of the muffler so it actually engages the outlet tube of the turned section, about 1/4" / 6mm. I was very fortunate to have this tubing which has been stored on the roof of my shed for years. No longer! I've made two of these modified mufflers; on both I had to break the pop-style rivets holding the sections together. I replaced the rivets with 6-32 (SAE) stainless steel screws after threading the ex-rivet holes. The mufflers were originally also bonded( sealed?) together with some sort of advanced adhesive. In both cases I had to burn that out( in the second case almost melting the alu casting.. :-( ) My first muffler was sealed with silicon rubber, the second with JB weld; in both cases I JB welded an appropriate metric screw in place of the pressure take off since I never use it. I cut off the excess and filed the remainder flush for a neater look. I plan to install one of these modified mufflers in the JagdPanther and hopefully post an "after" video so that the comparison may be analyzed. Jerry

I completed fitting of the modified muffler and had just enough time for a brief run. It seems to me to have reduced the higher pitched sounds ( scream) but I'll let the reader be the judge, As evidenced by my furry friends they didn't seem to be that bothered by it.

The steps of coversion

Note the copper bearing gasket forming sealant